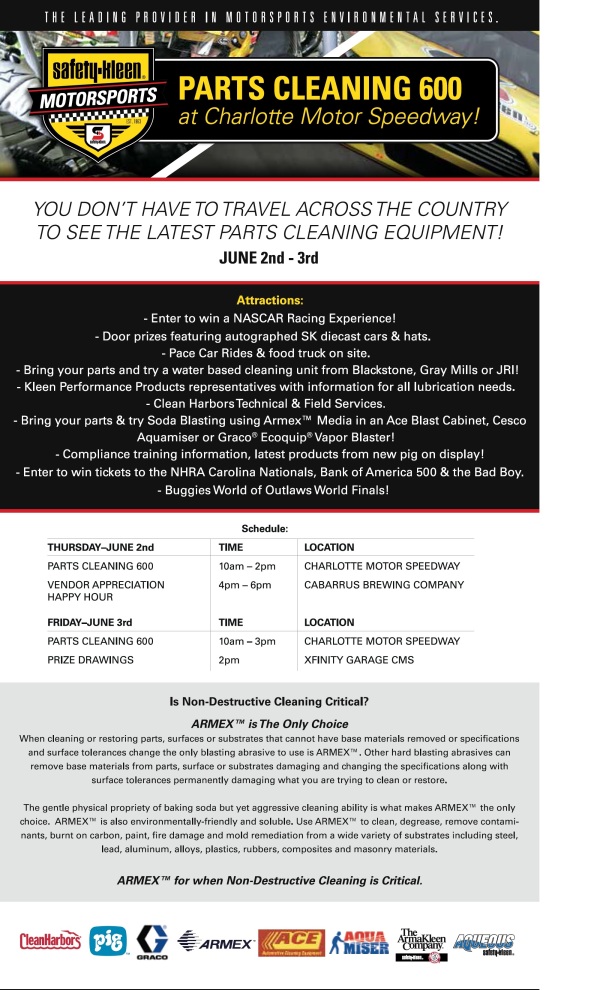

Mold damage before and after soda blasting (picture courtesy of ARMEX)

Hi Everybody! Welcome to my blog about soda blasting, the environmentally friendly cleaning method that uses a form of baking soda (sodium bicarbonate) in place of other non-environmentally friendly, and health hazardous blasting medias like sand.

Over the years, I have explained many different facets of the soda blasting process. Once you understand how soda blasting works, it is much easier to appreciate why it is such an effective, safe, and eco-friendly cleaning method for many different types of jobs. If you are a first time reader, I encourage you to look through past blog postings for a lot of great information. Here is a link to The Soda Blasting Guy archive of past blog postings:

https://sodablastingguy.wordpress.com/2017/06/26/index-and-links-archive-for-the-soda-blasting-guy/

Today I want to revisit a subject on which I have talked about before: soda blasting mold and fire damage. Unfortunately, many home owners are faced with the problem of restoring their property because of mold or fire damage. Whether caused by storms, floods, leaks or excessive humidity, mold can be a problem in attics, basements and crawl spaces. I have even talked with contractors who have encountered mold issues in new buildings currently under construction.

Fortunately, mold and fire damage are no match for soda blasting! Soda blasting not only cleans this type of damage, it also deodorizes.

As I discussed in one of my earlier postings, mold removal and fire damage restoration are some of the easiest jobs for a soda blaster to do. Mold removal and fire damage restoration usually can be done using lower blasting pressures than needed for other types of work. Using lower blasting pressure means that you use less soda blast media, making the job of mold removal and fire damage restoration more cost effective. You can also use a leaner soda to air mixture ratio, which again uses less soda blast media.

Labor efficiency is greater with soda blasting than with many other methods, especially with the use of a fan tip nozzle. A fan tip nozzle puts out a flat, blade type spray pattern, which is perfect for cleaning joists, studs, roof decking, brick, cement block or any type of surface, which has mold or fire damage. Use of a fan tip nozzle greatly improves speed for this kind of work. More efficient labor utilization means less time spent on the job site for improved profitability per job.

Here is a video showing soot, charring, and smoke damage sustained from a basement fire soda blasted using a fan tip nozzle and extension wand:

(Video courtesy of Paul Davis Restoration)

With more efficient labor utilization, less material usage, and deodorizing ability all wrapped up in an eco-friendly cleaning method, it is easy to understand why more and more mold remediation and fire damage restoration companies are choosing soda blasting to get the job done.

Here is a video from the Crawl Space Ninja talking about the use of soda blasting for mold removal:

(Video courtesy of Crawl Space Ninja)

I have found over the years that the most cost effective equipment setup for mold and fire damage cleanup is the ACE Model 2-PS Heavy Duty Portable Soda Blaster with the fan tip nozzle and extension wand. When used with a high quality soda blast media, such as Armex Flow M or Maintenance Formula, this setup delivers fantastic results. I have recommended this setup to many professional restoration companies, along with several hundred independent contractors, property management companies and individual home owners.

So whether you are a professional or do it yourself-er, soda blasting provides more efficient labor utilization, less material usage, and deodorizing ability all wrapped up in an eco-friendly cleaning method.

I hope this helps you out. In future postings, I’ll write about some of the other interesting projects that I’ve been involved with, using soda blasting. Soda blasting really is one of the most exciting, environmentally friendly cleaning processes available today. We are all put here on this planet for a short time, so let’s make the best of it and help preserve it for future generations.

Thanks for reading my blog! – The Soda Blasting Guy